Usually there are two forms of embossing. Embossing - which refers to the process of raised or relief impressions on sheet metals and paper embossing - which refers to the process of creating a raised or relief impression in paper to create a 3d effect in paper. You can also emboss other materials such as glass, this is done through heat.

Sheet metal embossing

The sheet metal embossing process is produced by matching male and female roller dies. A die is specialised tool used in manufacturing industries to cut or shape material using a press. Or it can be done by passing the material through rolls of the desired pattern.

Dies

Metal sheet is drawn through the male and female roller dies producing a pattern or design on the metal sheet. Depending on the roller dies used, different patterns can be produced on the metal sheet. This pressure and a combination of heat actually "irons" while raising the level of the image higher than the substrate to make it smooth. The term "impressing" enables one to distinguish an image lowered into the surface of a material, in distinction to an image raised out of the surface of a material"

"Embossing machines are generally sized to give 2" of strip clearance on each side of an engraved embossing roll. Many embossing machines are custom-manufactured, so there are no industry-standard widths. It is not uncommon to find embossing machines in operation producing patterns less than 6" wide all the way up to machines producing patterns 70"+ wide."

Commonly used materials in this process are zinc, aluminium, steel, copper, brass. This process is used for medium to high runs as it is consistent and reliable, it is able to consistently mould metal and for a long time depending on the longevity of the dies.

Paper Embossing

Embossing paper is accomplished by applying heat and pressure with male and female dies. Usually made of copper or brass. They fit together and squeeze the fibers of the material, creating the 3d effect. While the heat, in effect 'irons' the material.

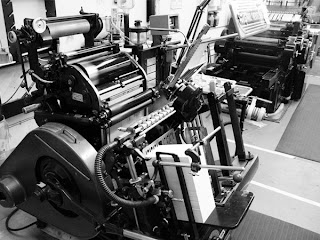

In print. This is accomplished with letterpress. The most common machines are the Kruge letterpess and Heidelberg letterpress...

Kluge Letterpres

Heidelberg press

Debossing is similar to embossing but recesses the design, rather than raising it. Check out these examples debossing..

You can see from some of the examples in this post, some stock is embossed or de-bossed with different colours in the embossed sections, some embossing is in conjunction with foiling or a spot varnish too. They all have specific names:

Blind embossing - Embossing without ink. so that the image is raised but not coloured. Probably the most popular and cost efficient method of embossing.

Colour register embossing - Embossing with ink, so that the raised area is coloured. I think most likely the area will have been inked first before embossing as trying to print onto a 3D embossed surface can't be too reliable.

Combination stamping - embossing used in conjunction with foil stamping or blocking.

Sometime's it's not just a design or a surface element but a usability element tied into the product itself. For example tissue paper and napkins and braille books.

Examples and process videos

Blind embossing

Blind debossing

Metal embos

Debossing into leather. This could have been done by applying a letterpress on top of the material and applying extreme pressure with a press.

Bling emboss. Deboss

Blind deboss

Blind emboss using an emboss die of varying levels and shapes to get this really cool 3d effect.

Combination stamp. Blind emboss + Foiling or a spot varnish

Combination stamping. Embossing in conjuction with foil blocking, or in this case it looks like a spot varnish.

Bling embossing, you see here how you can get quite intricate with the copy.

Bling embossing

Colour register embossing. This has been inked and the very slightly embossed. Gives a really cool, almost 'cooked' aesthetic, especially with the choice of stock.

Colour registration embossing again. A combination of ink and embossing.

Colour registration embossing again. A combination of ink and embossing. A business card this time.

Colour registration embossing again. A combination of ink and embossing. A business card this time.

Bling embossing for invitations is very popular, especially foiling plus embossing. A combination stamp, on wedding cards and invites.

Sources:

http://en.wikipedia.org/wiki/Embossing_(manufacturing)

http://en.wikipedia.org/wiki/Paper_embossing

It's really nice post. I would like to thank you for the efforts you have made in sharing this. Keep sharing Embossed Cards

ReplyDeleteI would love to get in contact with you. Please email me at avid.annie@gmail.com especially if you know of anyone who can create 3d emboss designs.

ReplyDeleteI would love to get in contact with you. Please email me at avid.annie@gmail.com especially if you know of anyone who can create 3d emboss designs.

ReplyDeletevideo is amazing. These four basic steps are useful and important one for making embossing die sets. Thanks for sharing the embossing process also.

ReplyDelete